In the fast-evolving landscape of logistics and heavy material handling, equipment performance is no longer just a support function — it’s a critical success factor. Downtime, inefficiency, and mechanical failure are not just technical issues — they are direct threats to profitability, safety, and reputation. Whether in high-volume seaports, offshore bulk terminals, or the rugged terrain of a scrap yard, the ability to move material safely, quickly, and precisely can make or break operations.

At Trio International, we understand that every second counts. Each grab, grapple, and material handling solution we develop is built around the realities of front-line operations — where environmental conditions are harsh, timelines are tight, and margins depend on seamless execution. That’s why we go beyond simply manufacturing equipment — we engineer productivity into every detail.

Our commitment is to deliver intelligent, robust, and application-specific solutions that not only meet the technical requirements of modern logistics and recycling workflows but also enhance long-term operational efficiency and worker safety.

This mindset drives our innovation. It’s why our grab and grapple systems feature industry-leading hydraulic power, optimized structural geometry, and compatibility with digital monitoring tools. It’s also why our equipment performs reliably under pressure — from the moment cargo hits the dock to the last ton of scrap being loaded for smelting.

Our equipment is trusted globally across industries where material handling isn’t just a task — it’s the core of the operation. From Asia’s busiest transshipment hubs to Europe’s leading recycling centers, from South American grain terminals to North African ore ports, our systems help businesses move more with less — less time, less energy, and less operational risk.

Unmatched Efficiency in Bulk Material Handling at Ports and Offshore Platforms

Why Grabs Matter in Marine Logistics

In port terminals and vessel environments, the capacity to move vast amounts of bulk material quickly and safely determines the profitability of each operation. Our grab systems are engineered to shorten loading and unloading cycles, minimize vessel idle time, and enhance berth productivity — all while maintaining exceptional safety standards.

Advanced Hydraulic and Electro-Hydraulic Grabs

We offer a wide range of grab units in hydraulic, electro-hydraulic, and mechanical configurations, ensuring compatibility with all major crane systems, including:

Ship-mounted cranes

Port and harbor cranes

Gantry and mobile cranes

Floating crane systems

Electro-hydraulic grabs include integrated power packs, eliminating the need for external hydraulic infrastructure — ideal for vessel retrofits and offshore platforms.

Engineered For Optimal Performance

Our grab designs are the result of finite element analysis (FEA), field testing, and continuous feedback from frontline operators. Key features include:

Open and closed shell configurations

Optimized weight-to-load ratio for higher material throughput

Fast open/close cycles to reduce ship dwell time

Custom shell geometry for cohesive material flow

Tailored For Operational Realites

Each operation is unique, which is why we offer fully customized grab configurations based on:

Safe Working Load (SWL) of cranes

Density, cohesiveness, and flow properties of cargo

Drop height and operational speed

Environmental factors like wind, humidity, and corrosive exposure

We specialize in grabs for materials such as:

Coal, grain, bauxite, phosphate, cement clinker

Iron ore, copper concentrate, sand, limestone

Biomass, wood chips, agricultural products

Built to Last in Harsh Marine Environments

Every component is constructed using high-tensile steel, hardened pins, abrasion-resistant coatings, and IP-rated hydraulic components. Our solutions are built for continuous 24/7 operation, with minimal maintenance.

Integration with Port Automation Systems

All Trio grab models are designed to integrate with:

Load and torque sensors

Digital crane control systems (DCCS)

Automated Terminal Operating Systems (TOS)

Remote condition monitoring platforms

This connectivity ensures better data tracking, predictive maintenance, and operational efficiency.

Engineered Tough for Demolition, Metal Recycling & Waste Processing

Meeting the Challenges of Scrap Handling

Scrap material handling is unpredictable — full of irregular shapes, sharp edges, and heavy debris. Trio International’s grapple systems are built to withstand abuse, maintain productivity, and enhance precision, no matter how extreme the environment.

Multi-Tine Grapples(Orange Peel Style)

Our industry-leading multi-tine grapples are built for maximum grip strength and penetration. Designed to enclose, grab, and secure odd-shaped, abrasive materials, these grapples are essential for:

Metal scrap yards

Auto recycling and car dismantling

Construction and demolition (C&D) waste

Large appliance disposal

Foundry charging

Key specifications:

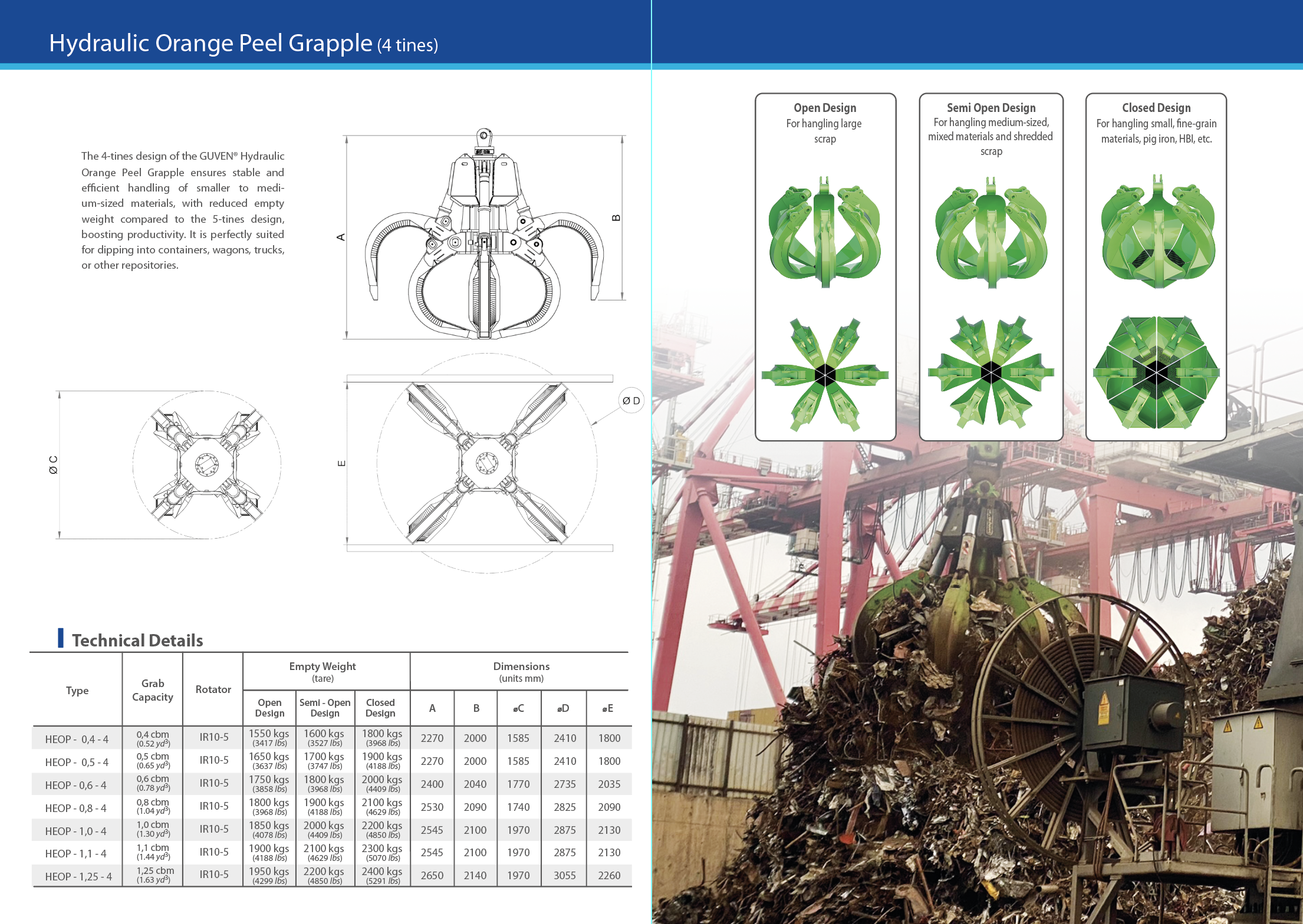

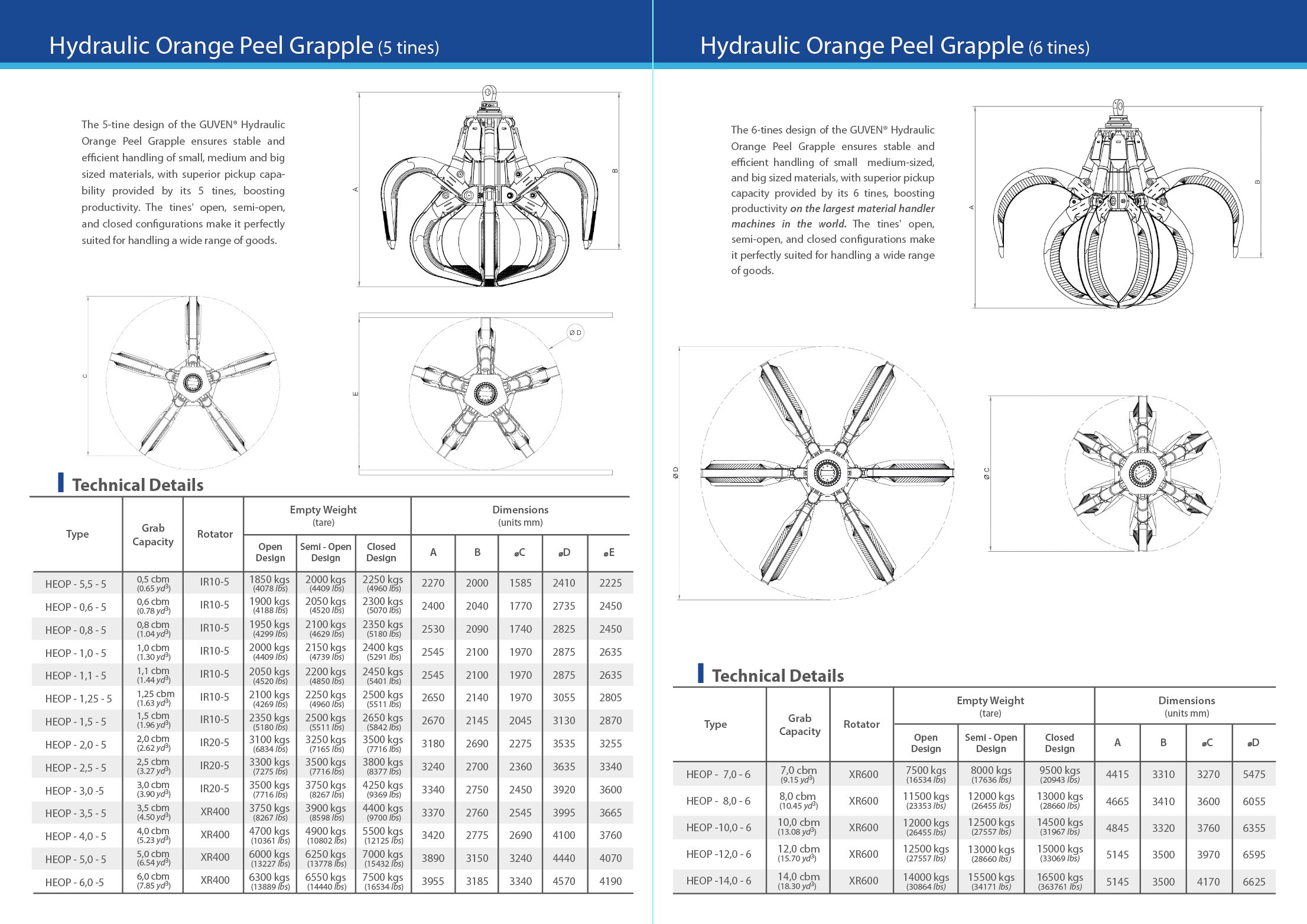

4, 5, or 6 tines depending on material characteristics

Open, semi-closed, and closed tine configurations

High-grip profiles to minimize drop and spillage

Superior Control with 360° Hydraulic Rotation

Each grapple is equipped with continuous rotation hydraulic motors, allowing precise movement even in confined spaces. This enables:

Faster material sorting

Accurate placement in containers

Safer operation near structures or personnel

Built for Longevity and Strength

We use only the highest-grade components for our grapples:

Oversized hydraulic cylinders with shock protection

Double-welded tines and high-wear tip plates

Replaceable bushings and pins

Hardox®-equivalent armor plating on contact surfaces

Maximum Versatility

Our grapples are compatible with:

Crawler and wheeled excavators (15T–80T class)

Stationary pedestal-mounted systems

Rail and truck-mounted cranes

High-reach material handlers

We also offer quick coupler compatibility and customized mounting brackets to support fleet flexibility.

Easy Service, Maximum Uptime

The modular design of our grapples allows for quick disassembly and replacement of worn parts. Maintenance access points are engineered for:

Quick daily checks

Field repairs without disassembly of the entire unit

Minimized downtime with readily available spares

At Trio International, sustainability is integrated into everything we build. Our grabs and grapples help:

Optimize resource use by minimizing fuel consumption and equipment cycles

Reduce emissions through faster material transfer

Extend product life with serviceable designs and robust components

Promote recycling efficiency, boosting the profitability of circular economy sectors

We proudly serve clients in:

International seaports and logistics hubs

Municipal and industrial waste processors

Metal and electronics recyclers

Demolition contractors and infrastructure rebuilders

Smelters and steel plants

With a presence in over 40 countries, Trio International supports its customers with:

Turnkey system installations

Operator and technician training

Rapid spare parts supply chain

24/7 multilingual technical support

Preventive maintenance programs

Our solutions are trusted by global logistics leaders, engineering firms, and sustainability-focused companies that demand nothing less than excellence.

Every material is different. Every crane is different. Every job is different.

That’s why we don’t sell products — we deliver engineered solutions. Contact our team today to discuss your project’s unique material handling needs and discover how Trio can help you lift your productivity to the next level.